Plastic Machined Parts

Home > Products > By Applicaitons > Plastic Machined Parts > abrasion resistant UHMWPE machined products plastic partsXINXING can make custom UHMW Machined Parts to your specifications or drawings.

MATERIAL DESCRIPTION

UHMW stands for ultra high molecular weight polyethylene or UHMWPE.

Polyethylene materials are semi-crystalline materials with excellent chemical resistance, good fatigue and wear resistance, and a wide range of properties (due to differences in length of the polymer chain).

Polyethylene materials are easy to distinguish from other plastics because they float in water. Polyethylene materials provide good resistance to organic solvents, degreasing agents, and electrolytic attack.

They have a higher impact strength, but lower working temperatures and tensile strengths than polypropylene. They are light in weight, resistant to staining, and have low moisture absorption rates.

Images of all kinds of UHMWPE parts

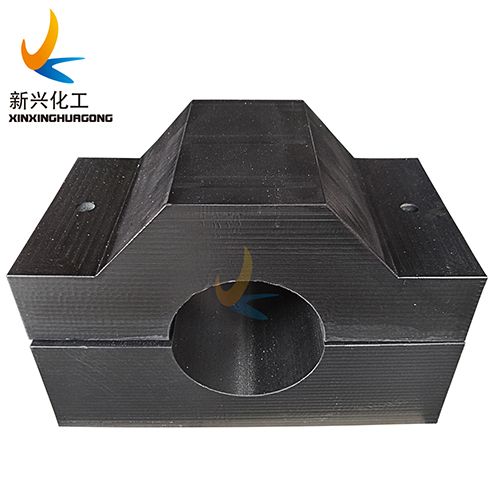

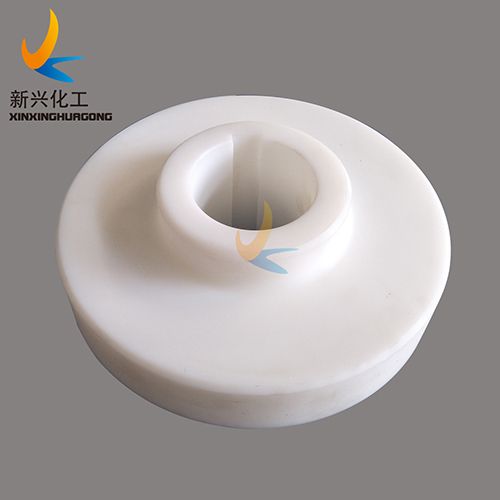

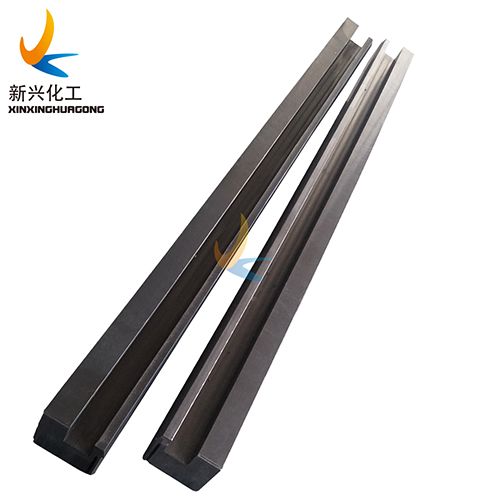

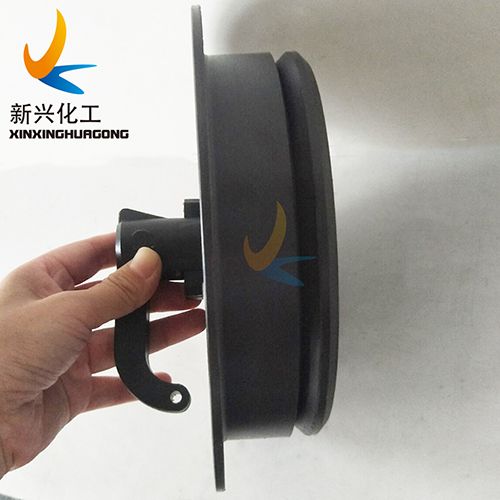

abrasion resistant UHMWPE machined products plastic parts

abrasion resistant UHMWPE machined products plastic parts

abrasion resistant UHMWPE machined products plastic parts

abrasion resistant UHMWPE machined products plastic parts

Advantages of UHMWPE machined parts

Advantages of UHMWPE irregular parts:

1.Abrasion highest plastic, seven times higher than carbon steel, four times higher than PTFE.

2.Self-lubricating performance

3.Impact strength, 2 times higher than that of polycarbonate, 5 times higher than ABS.

4.Nonstick surface of product compared with other materials is not easy to attach, strong anti-adhesion properties.

5.Corrosion resistance: at a certain temperature and humidity resistant to concentrated acid, alkalis, corrosive chemicals, high chemical stability.

Application of UHMWPE machined products:

Augers

Bearings and bushings

Chain guides, sprockets and tensioners

Chute and hopper liners

Deboning tables

Flights and gears

Guide rails and rollers

Mixer bushings and paddles

Scraper and plow blades

UHMWPE is used where sliding abrasion occurs or where metal parts meet, causing friction or abrasion wear. It is excellent for chute and hopper liners, convey or components, wear pads, machine guides, impact surface and guide rails.

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.