UHMWPE conveyor roller

HDPE/UHMWPE roller idlers for self cleaning used on the transom to support the belt when the material being conveyed, performs a cleaning action and reduces the tendency of material to deposit itself and stick to the surface of the dirty side of the belt.

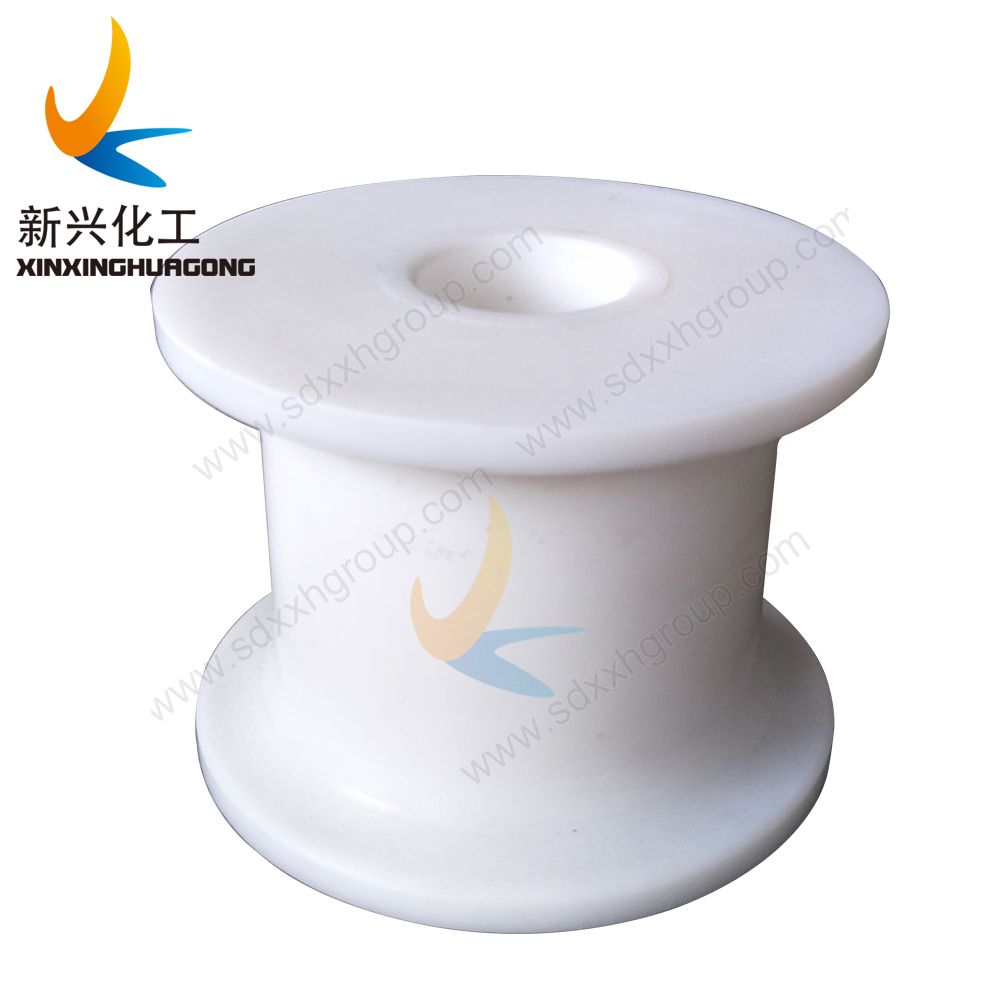

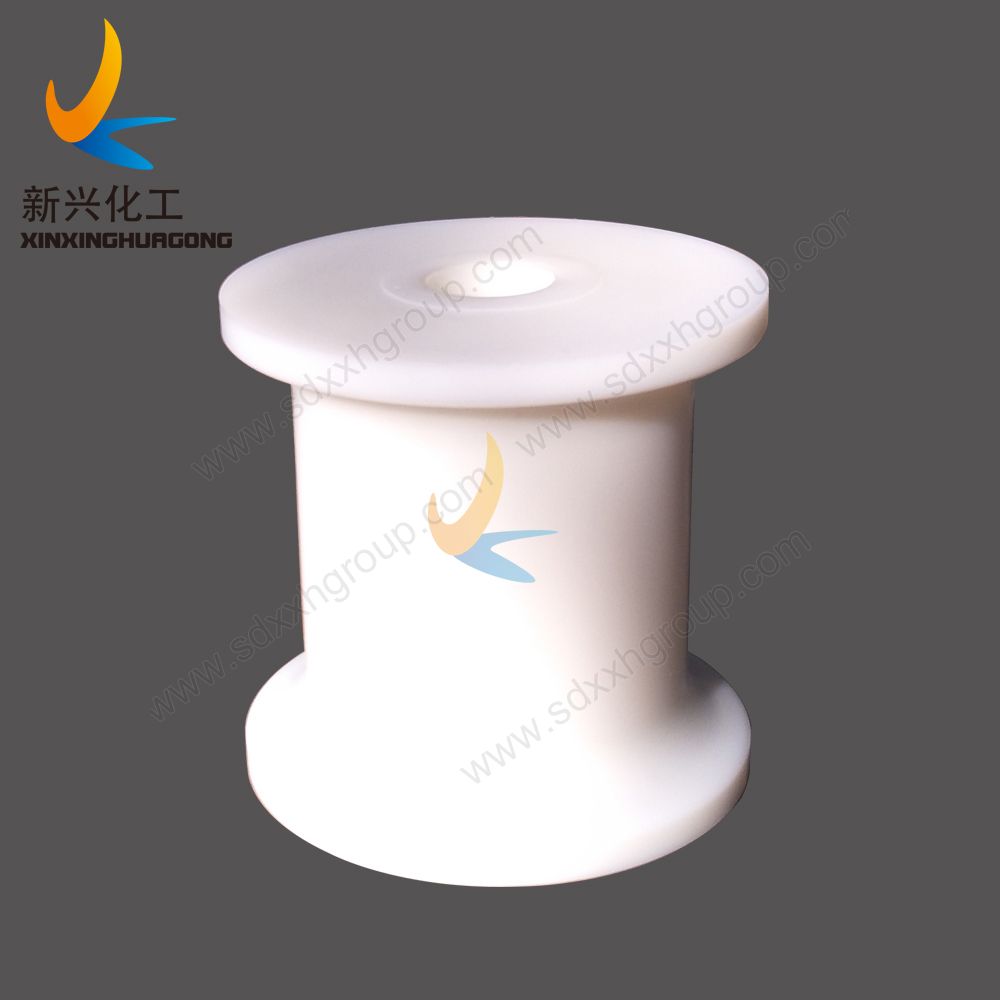

images of UHMWPE rollers

![UHMWPE conveyor roller UHMWPE conveyor roller]()

UHMWPE conveyor roller

![UHMWPE conveyor roller UHMWPE conveyor roller]()

UHMWPE conveyor roller

![UHMWPE conveyor roller UHMWPE conveyor roller]()

UHMWPE conveyor roller

UHMWPE conveyor roller idlers Advantages

HDPE/UHMWPE conveyor roller idler:

Typical application for the rollers are: mines, quarries, cement plants, coal-fired power plants, port installations. The effectiveness of the HDPE roller system provides the solution to the environmental challenges of dust, dirt, water, low and high temperatures or applications where there is a large temperature gap between day and night. The working temperature, with standard greased components is defined as between -100°C and + 80°C. It is possible to reach temperatures outside of this range using special grease, bearings and seals.

HDPE/UHMWPE roller idlers for self cleaning used on the transom to support the belt when the material being conveyed, performs a cleaning action and reduces the tendency of material to deposit itself and stick to the surface of the dirty side of the belt. They may be employed on any part of the return belt section in the case of short conveyors. On long sections it is satisfactory to employ these rollers only up to the point where the material does not adhere any more to the belt surface. These rollers should not be employed as snub rollers adjacent to the drive or return drums.

Characteristics for Transport Roller:

1. High-wear resistance seven times wear resistance than steel, four times than PTFE.

2. High impact resistancetwo times impact resistance than PC, five times than ABS.

3. Self-lubrication the same as PTFE, better than steel and brass appended lubricating oil.

4. Anti-corrosion resistance,stable chemicals property and can endure the corrosion of all kinds of corrosive medium and organic solvent in certain rang of temperature and humidity.

5. Non-sticking the smooth surface of product hardly affixes other material.

6. Low temperature resistancein (-196), it still has the prolongation and high tensile strength.

7. Non-toxic and clean property.

Specification and our service

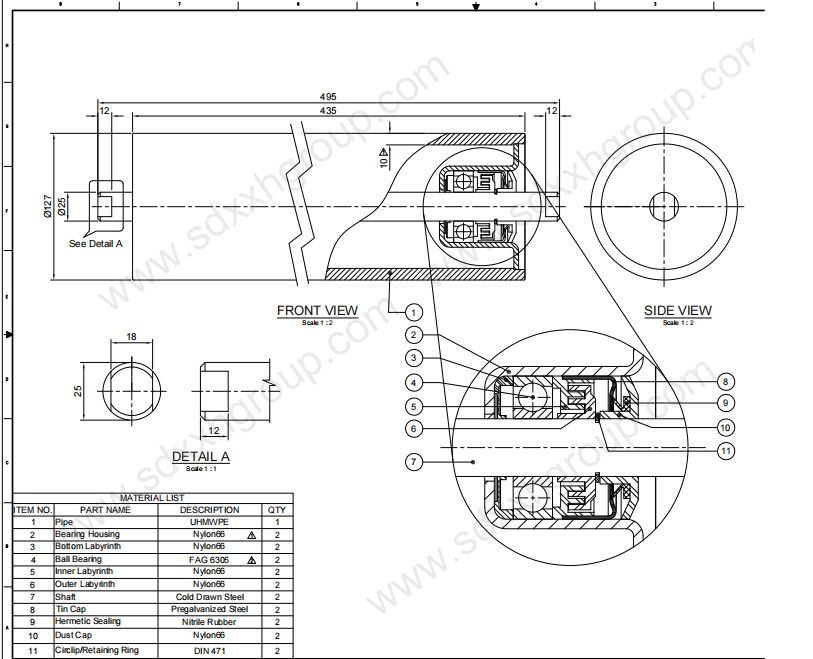

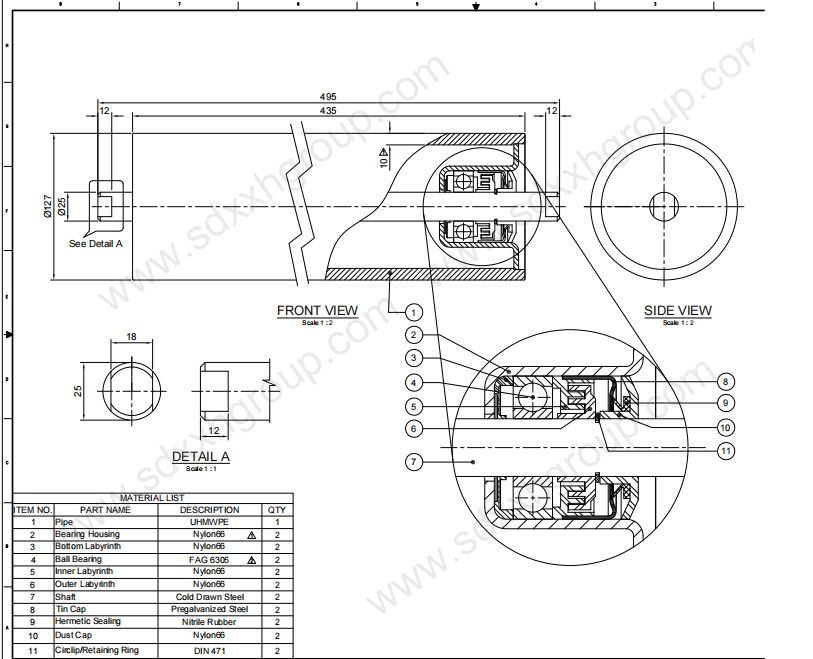

We accept OEM rollers, please provide drawings as bellow:

UHMWPE Roller, the surface adopts 100% UHMWPE material,famous bearing brand possessing excellent performance:highly self-lubrication,good wear-ability, and anti-aging .Rotary flexible makes it stands 3,000 hours of rotatory, and reliable up to 3 years.

More than 20 years focusing on quality, serving thousands of major customers.

Welcome to contact and cooperate with us! [email protected]