UHMWPE/HDPE Rod is an excellent engineering plastic that can solve many problems while others cannot. UHMWPE/HDPE Rod is not as widely known as other engineering plastics such as Nylon Rod but is still very important and helpful than the more common engineering plastics because of its distinct advantages.

Here you can find all kinds of HDPE Sheet you want!

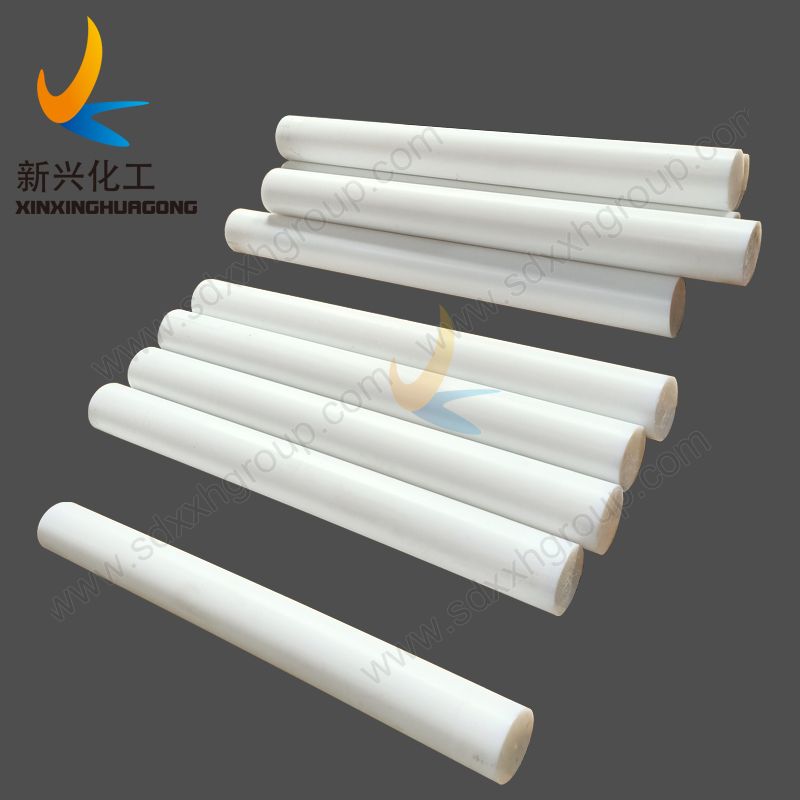

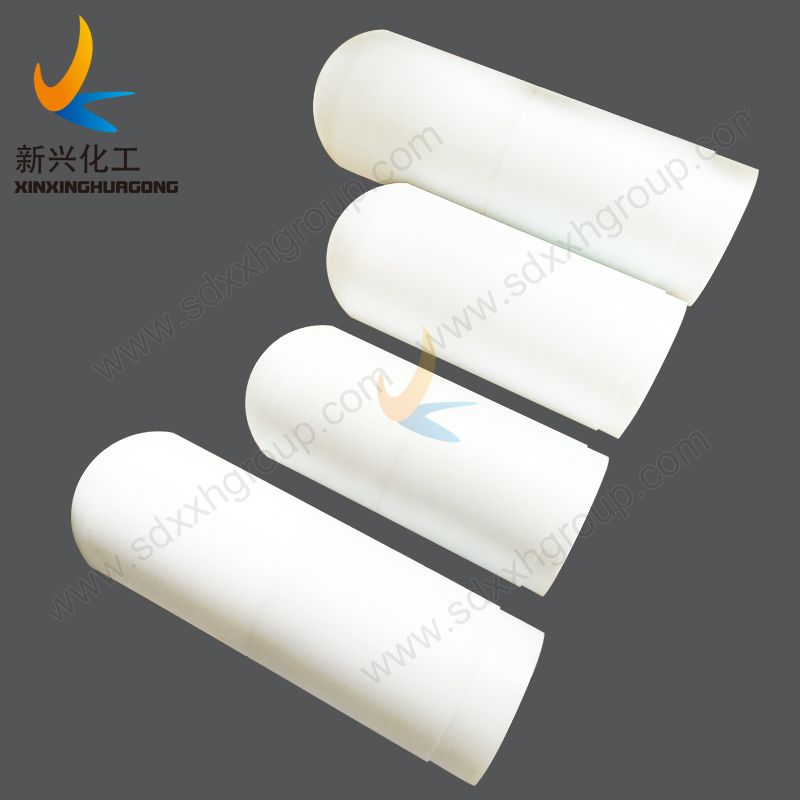

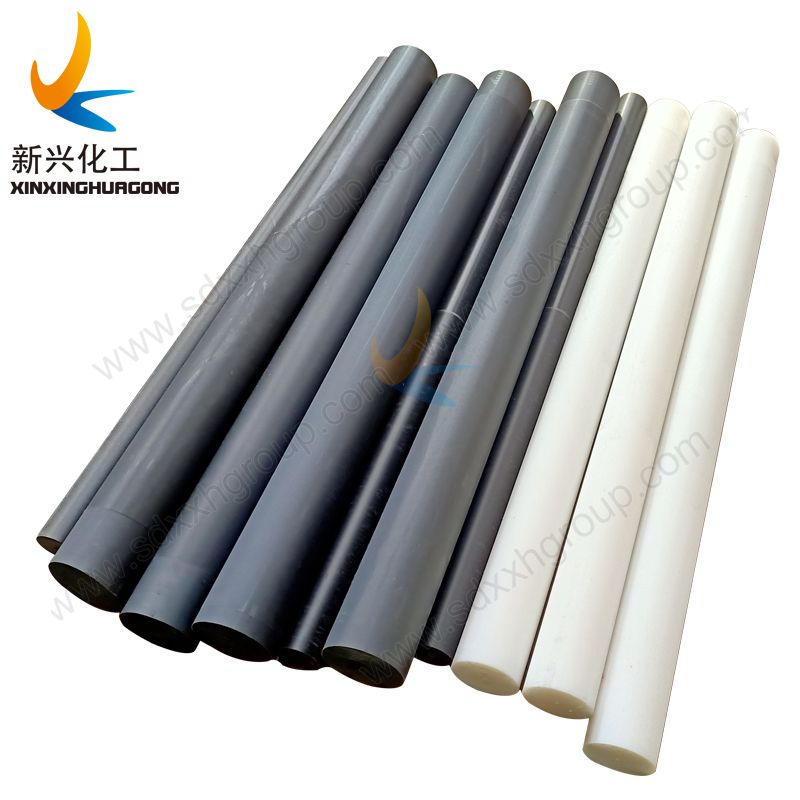

high-density polyethylene rod

high-density polyethylene rod

high-density polyethylene rod

high-density polyethylene rod

high-density polyethylene rod

Advantages of HDPE/UHMWPE ROD

UHMWPE/HDPE Rod takes great advantage of its low co-efficient of friction which means it will produce bearings, pulleys or bushes that are very free running, low friction and long lasting. UHMWPE Rod is also very abrasive resistant, this means that UHMWPE Rod can survive longer than other materials when used in high demand environments such as grit or gravel. UHMWPE Rod can often be used in high demand components in the food industry, this is because it has a very low moisture absorption that gives UHMWPE Rod an FDA approval and means that bearings etc. will not expand due to any moisture absorption. Another reason that UHMWPE Rod is also used in the marine industry for pulleys is its low friction and minimal moisture absorption.

Product description

Physical character: Made with 100% virgin HDPE which is known for its high quality and cost-effective rates. It is no poison, low temperature tenacity, good twisting endurance, excellent chemical erosion, superficial electrical performance within wide frequency range, etc and more rigid and harder than LDPE(low density PE) materials and is three times better in compressive strength. These sheets are widely used in different applications. With High tensile strength, Lightweight, chemical and corrosion resistant, Thermoforming performance, No moisture absorption, Non-staining, Non-Toxic. Apply to cutting boards, tanks, trays, water storage, light duty chain guides, secondary containment of chemical industry, electrical power, package and other industries.

Specifications:

Material: 100% virgin HDPE

Color: White, black etc.

Surface: Smooth

Produce: Extrude

Tensile strength: 23Mpa

Elongation: 60%

Density: 0.96-0.98g/cm3

Impact strength: 5KJ/m2

Vicat softening temperature: 125° C

Heat deflection temperature: 90° C

Standard size: Ø 2-300mm x 1000mm

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.