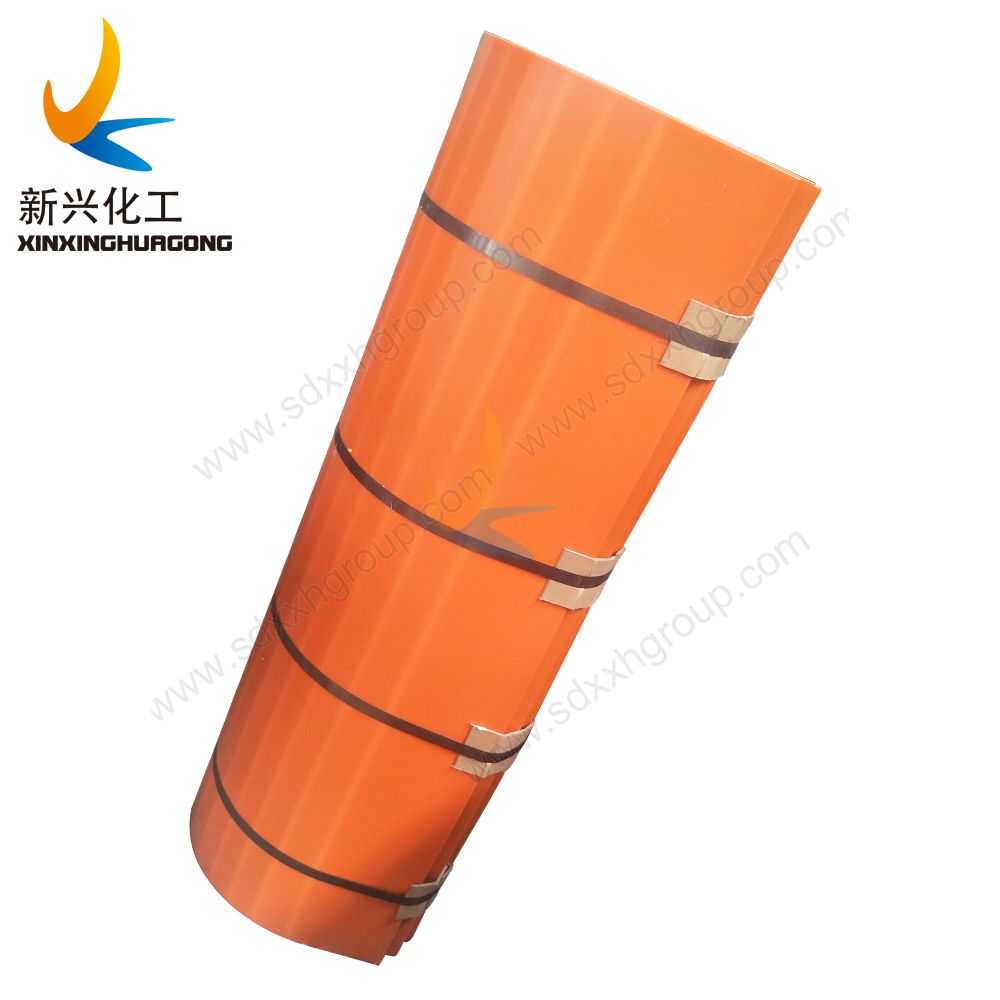

UHMWPE sheet is engineering plastic panel can be machined into virtually anything, from small gears and bearings plates to huge wear guides that until recently were only possible with metals. It not only outperforms metal in abrasion applications, it's also easier to machine and therefore cheaper. This versatile plastic can be milled, planed, sawed and drilled to create a huge variety of parts at a very competitive price. UHMWPE sheet has an exceptionally low coefficient of friction which offers superb sliding properties and is one of the best materials for wear and abrasion resistance. UHMWPE Sheet is tough even at low temperatures, it offers low weight, and is easy to weld.

Applications of UHMWPE sheet

corrosion resistant UHMWPE sheet

corrosion resistant UHMWPE sheet

corrosion resistant UHMWPE sheet

corrosion resistant UHMWPE sheet

UHMWPE Sheet Advantages

Advantages:

1, good cold resistance, ultra-high molecular weight polyethylene under liquid nitrogen or liquid helium, so that the temperature reaches 269 ℃, has extended and the performance of high strength, there is still a certain mechanical strength, make its perennial fray in seawater immersion won't occur, can be used in water medium.

2, low water absorption, not affected by the temperature.

3. Stable corrosion resistance, strong corrosion resistance, able to resist corrosion resistant substances and organic solvents within a certain range.

4, excellent high impact resistance, good toughness, good environmental stress resistance, good environmental stress fracture resistance is 200 times than ordinary ethylene.

5, good anti-ultraviolet performance, long service life. Excellent abrasion resistance, good resistance to low temperature impact, self-lubricating, non-toxic, water resistance, chemical resistance, heat resistance is better than ordinary PE.

Technical Data:

Property | Unit | Value |

Density | g/cm3 | 0.93-0.96 |

Average molecular weight | g/mol | 3million- 10 million |

Tensile strength (23°C in air) | MPa | 22 |

Breaking strength | MPa | 42 |

Tensile strain at break | % | 600 |

Charpy impact strength (notched) | mJ/mm2 | No break |

Ball indentation hardness | N/mm2 | 42 |

Shore hardness | -- | 65-70 |

Abrasion | % | 70-80, steel = 100 |

Static Friction Coefficient | -- |

≤0.16 |

Kinetic Friction Coefficient | -- |

≤0.10 |

Water Absorption | -- | NIL |

Elongation at break at 23°C | % | ≥300 |

Temperature Resistance | °C | -269 to +85 |

Melt Temperature | °C | 130-140 |

Application of UHMWPE sheet

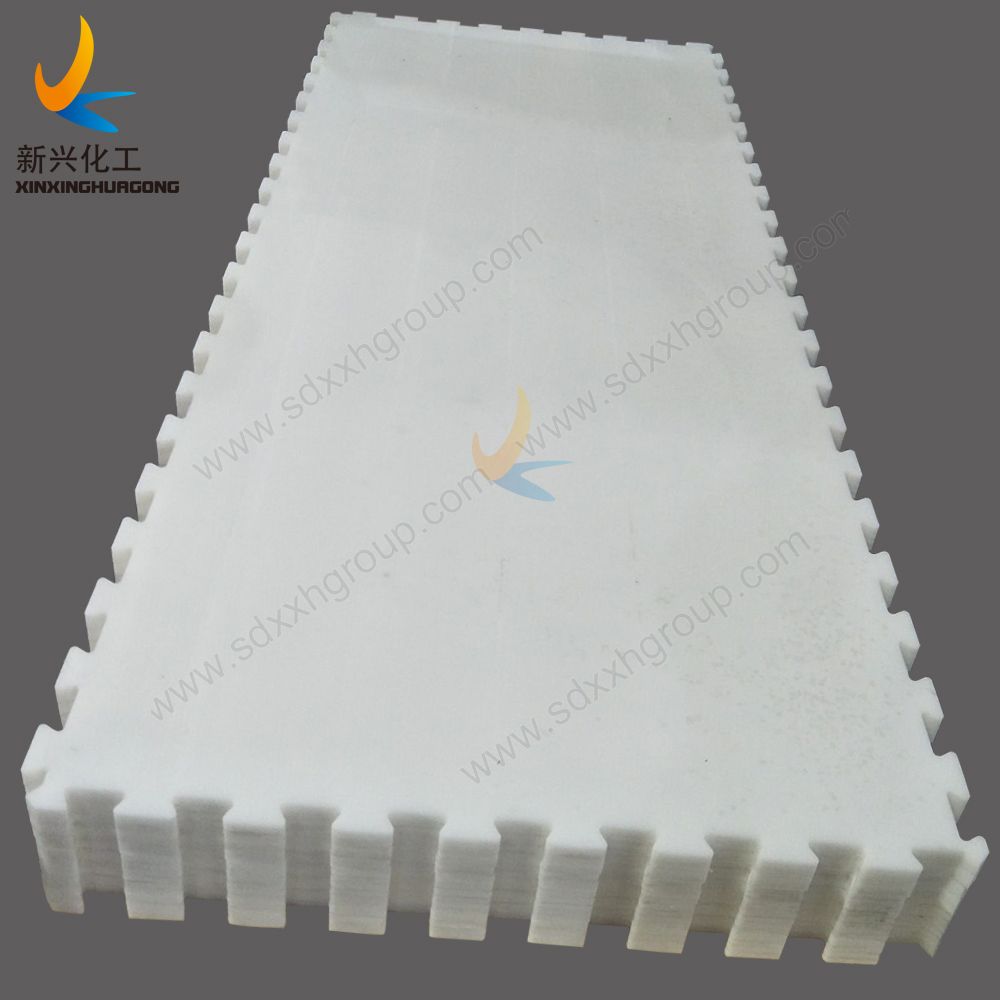

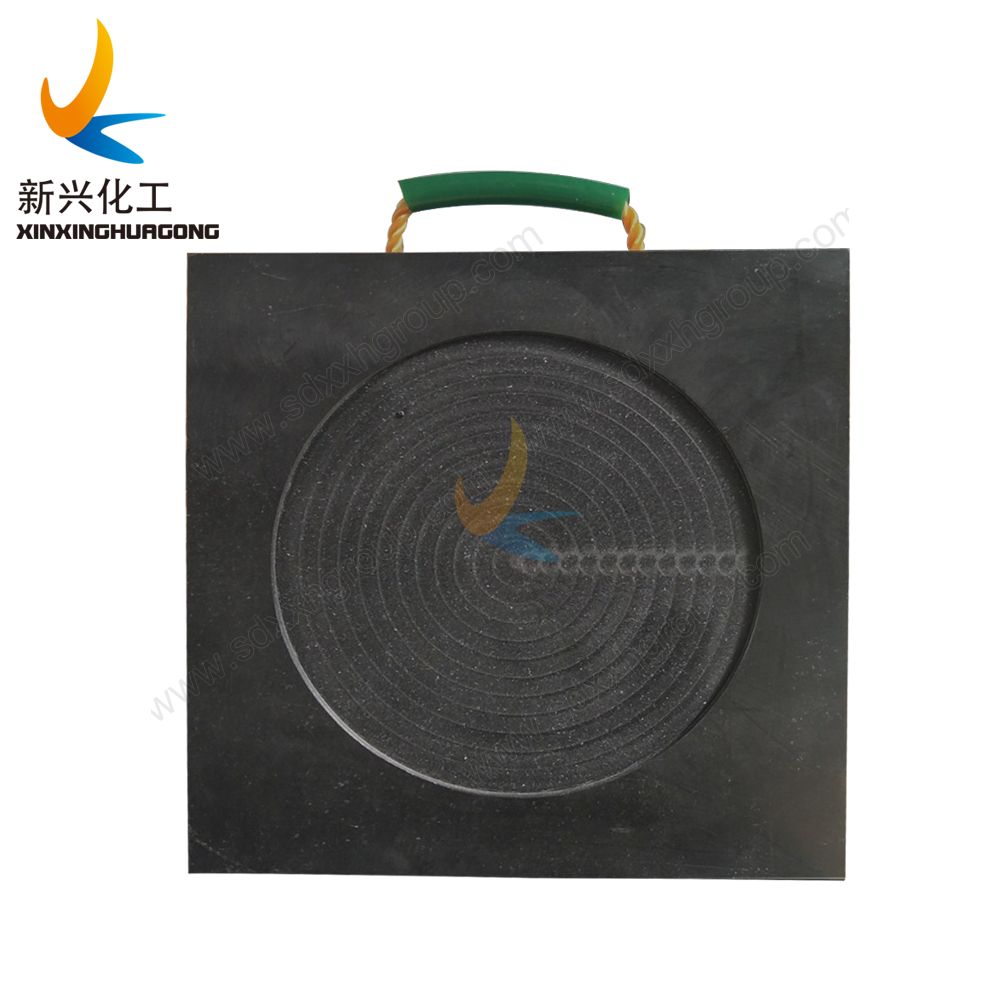

1.Lining: Silos, hoppers, wear-resistant plates, brackets, chute like reflux devices, sliding surface, roller, etc.

2. Food Machinery: Guard rail, star wheels, guide gear, roller wheels, bearing lining tile, etc.

3. Paper-making machine: Water lid plate, deflector plate, wiper plate, hydrofoils.

4. Chemical Engineering: Corrosion and wear-resistant mechanical parts

5. Other: Agricultural machinery, ship parts, electroplating industry, extreme low temperature mechanical components.

6. Thermal power: coal handling, storage of coal, coal bunker lining

7. Coal processing: sieve plate, filter, U-underground coal chute

8. Concrete: cement raw and finished product silo silo lining

9. Grain: food storage or chute lining

10. Mining: sieve plate, chute linings, wearproof anti-bonding part

11. Some kind of rubber fender panels and front face of rubber fender

12. Other fields include Ice rink, water tank etc.

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.