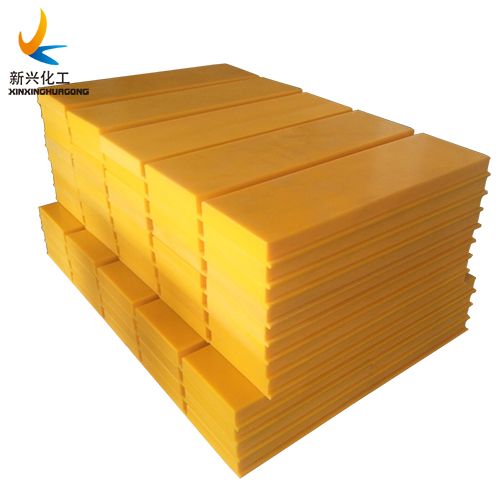

UHMWPE Sheet

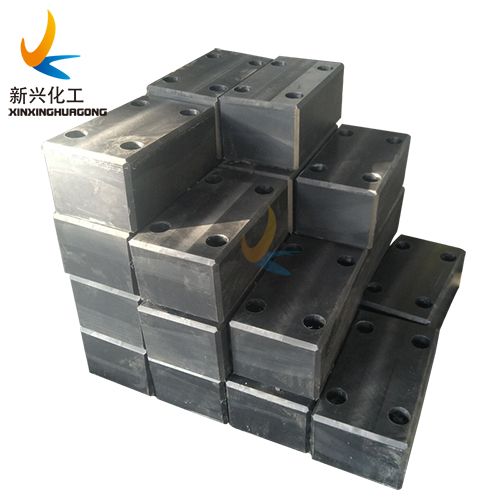

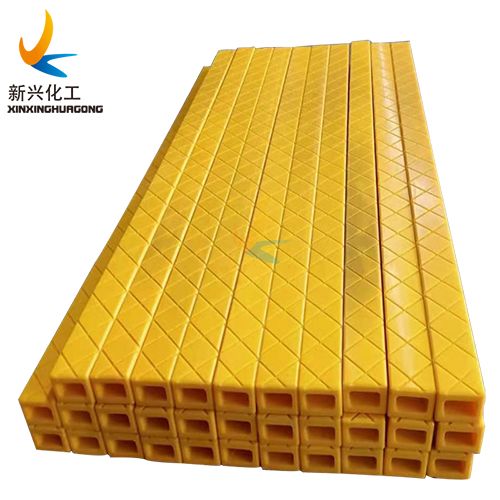

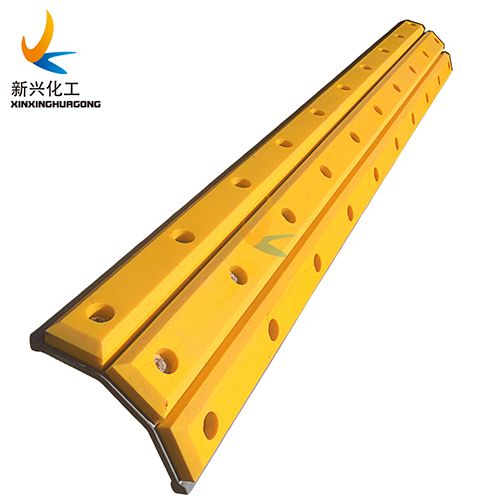

Home > Products > By Material > UHMWPE Sheet > UHMW MACHINED PARTS PE1000 wear Strip UHMWPE sheetIntroduction of UHMWPE sheet/PE-1000 wear strips

UHMWPE sheet is nontoxic, feel like wax, has good low temperature resistance (the lowest temperature can reach 70 - 100°C), chemical stability is good, most of acid and alkali erosion (acid) with characteristics of oxidation resistance, Normal temperature does not dissolve in solvents, small water inhibition, excellent electrical insulation properties, Low density, Good toughness, also apply to low temperature conditions,

Good strength ability

The electric and dielectric insulation

Bibulous rate is low

The water vapor permeability is low

Good chemical stability

Nontoxic harmless.

Medical appliance parts, seals, cutting boards, sliding profiles.

Widely used in chemical industry, machinery, chemical industry, electric power, clothing, packaging, food and other industries.

Widely used in gas transmission, water supply, drainage, irrigation, mines fine particles of solid conveying, and oil field, chemical industry and telecommunications and other fields, especially on the gas supply has been widely used.

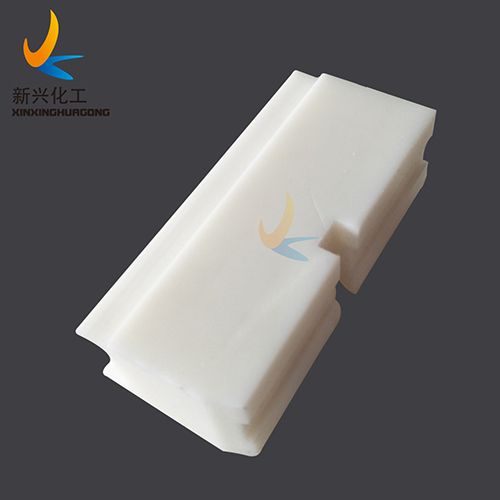

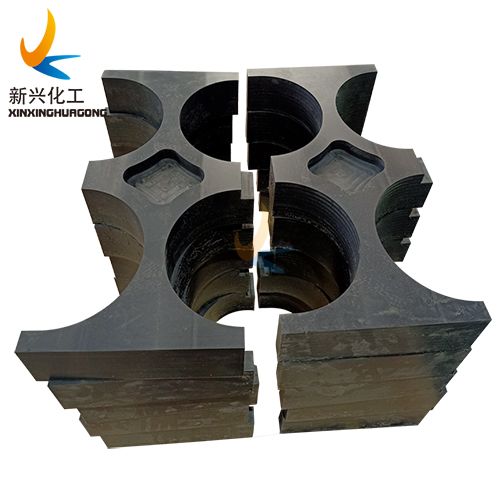

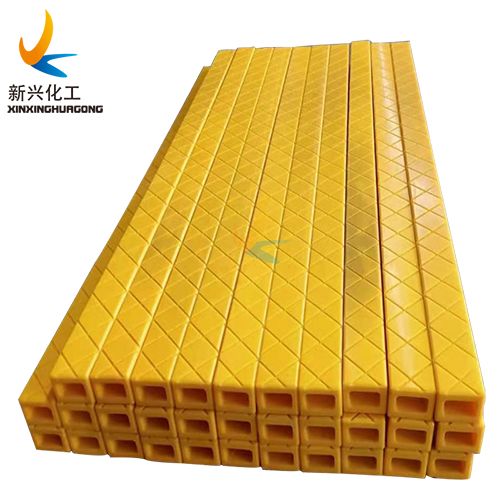

UHMWPE sheet Plastic wear strip Pe blocks

UHMW MACHINED PARTS PE1000 wear Strip UHMWPE sheet

UHMW MACHINED PARTS PE1000 wear Strip UHMWPE sheet

UHMW MACHINED PARTS PE1000 wear Strip UHMWPE sheet

UHMW MACHINED PARTS PE1000 wear Strip UHMWPE sheet

UHMWPE Sheet Advantages

As a new type of engineering plastic, UHMWPE sheet possesses multiple performance advantages:

Extraordinary wear-resistant,4~6 times higher than other plastic,6~9 times higher than steel, and 26 times higher than copper.

Highly impact strength, 10 times higher than PA6 and PP

Low friction coefficient (0.05~0.11), and capable of self lubrication

Unattractive to foreign material, and anti-sticking while sliding

Resistant to chemical corrosion

Parameter of UHMWPE sheet:

| Items | Unit | Data | ASTM Test Method |

| Molecular Weight | billion | 3~9 | D2857 |

| Specific Gravity | g/cm^3 | 0.935~1.0 | D1505 |

| Tensile Strength | MPa | 40~45 | D638 |

| Elongation at break | % | 300~400 | D638 |

| Impact Strength | kJ/m^2 | ≥140 | D250 |

| Rockwell Hardness | kJ/m^3 | 40~60 | D747 |

| Abrasion Loss | mg/1000 times | 70 | D1175 |

| Distortion Temperature | ℃ | 85 | D648 |

Application of UHMWPE blocks plastic parts

1.Lining: Silos, hoppers, wear-resistant plates, brackets, chute like reflux devices, sliding surface, roller, etc.

2. Food Machinery: Guard rail, star wheels, guide gear, roller wheels, bearing lining tile, etc.

3. Paper-making machine: Water lid plate, deflector plate, wiper plate, hydrofoils.

4. Chemical Engineering: Corrosion and wear-resistant mechanical parts

5. Other: Agricultural machinery, ship parts, electroplating industry, extreme low temperature mechanical components.

6. Thermal power: coal handling, storage of coal, coal bunker lining

7. Coal processing: sieve plate, filter, U-underground coal chute

8. Concrete: cement raw and finished product silo silo lining

9. Grain: food storage or chute lining

10. Mining: sieve plate, chute linings, wearproof anti-bonding part

11. Some kind of rubber fender panels and front face of rubber fender

12. Other fields include Ice rink, water tank etc.

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.