Abrasion Resistant UHMWPE liners

Home > Products > By Applicaitons > Abrasion Resistant UHMWPE liners > abrasion resistant UHMWPE liner for bunkerUHMWPE sheet has an incredible resistance to abrasion. It will outperform almost any engineering plastic for abrasion resistance and is probably one of the best materials for lining chutes and hoppers for products such as sand, aggregate and concrete or any other highly abrasive moving product.

Another important property is it's incredibly low co-efficient of friction. It is one of the lowest of all engineering plastics and will produce components with a very high life span with very low drag, which means very little will stick to it. Its also resistant to many dilute acids, solvents and cleaning agents.

UHMWPE has a maximum continuous operating temperature of plus 90°C and a short term operating temperature of plus 120°C. Its a very tough material, with the highest impact strength of any thermoplastic presently made.

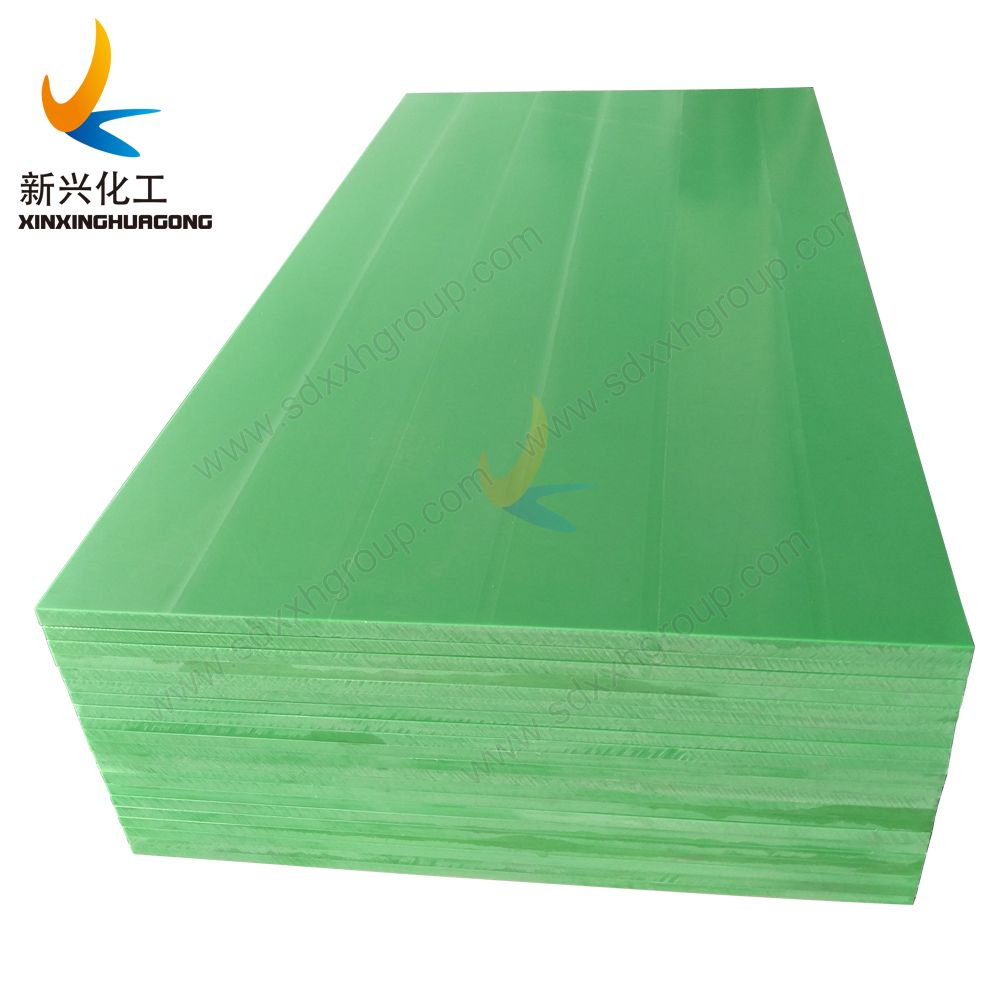

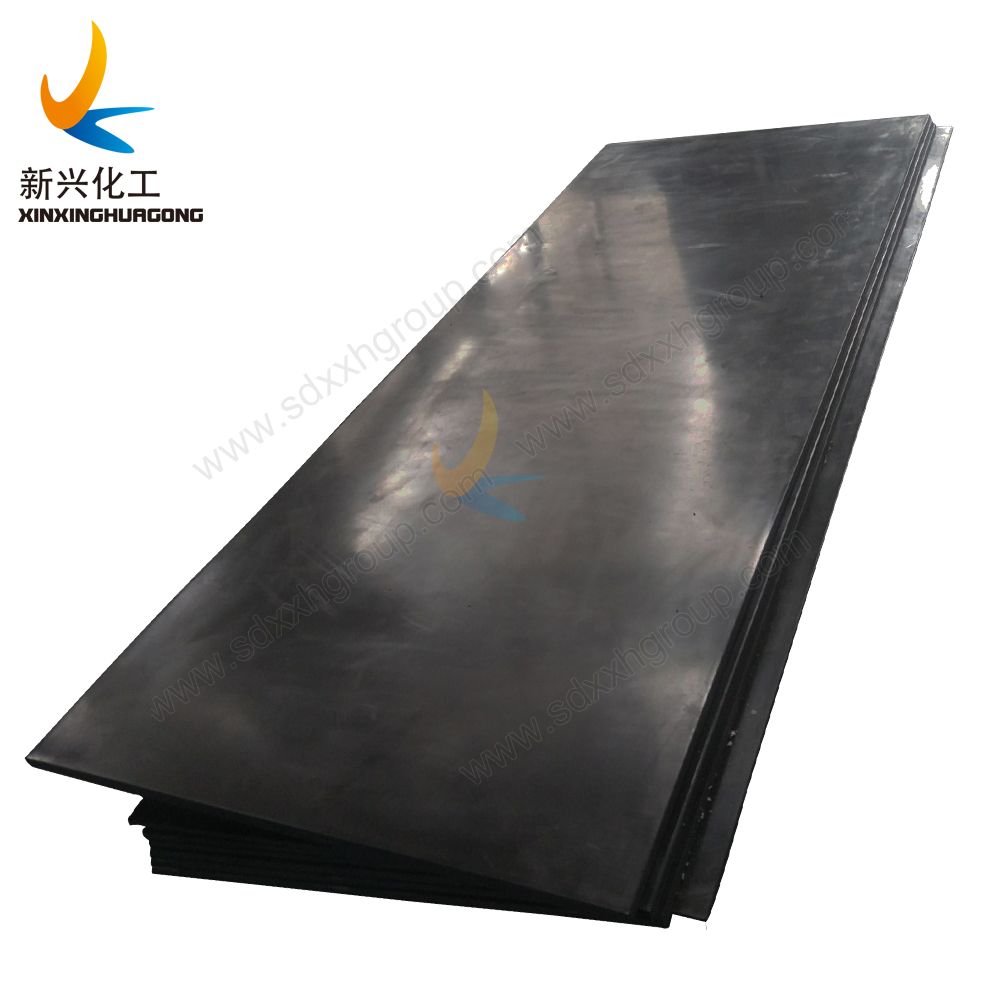

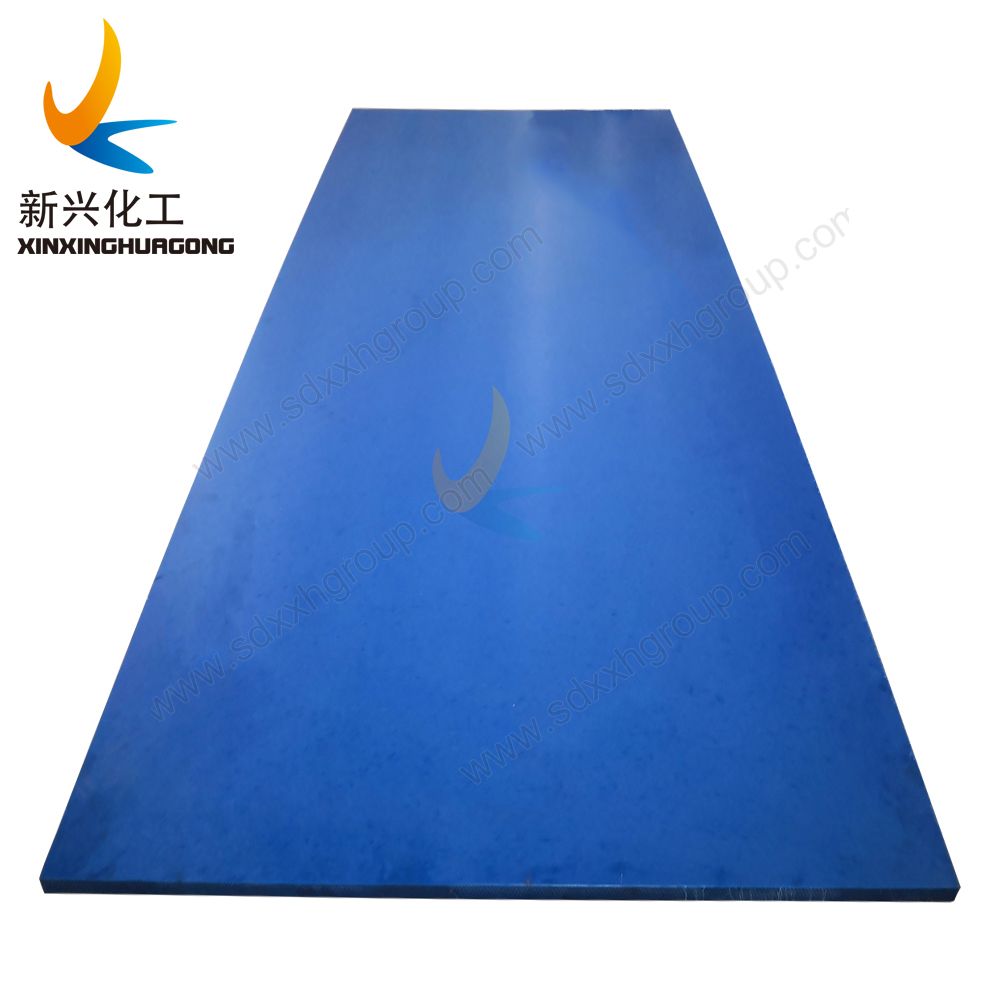

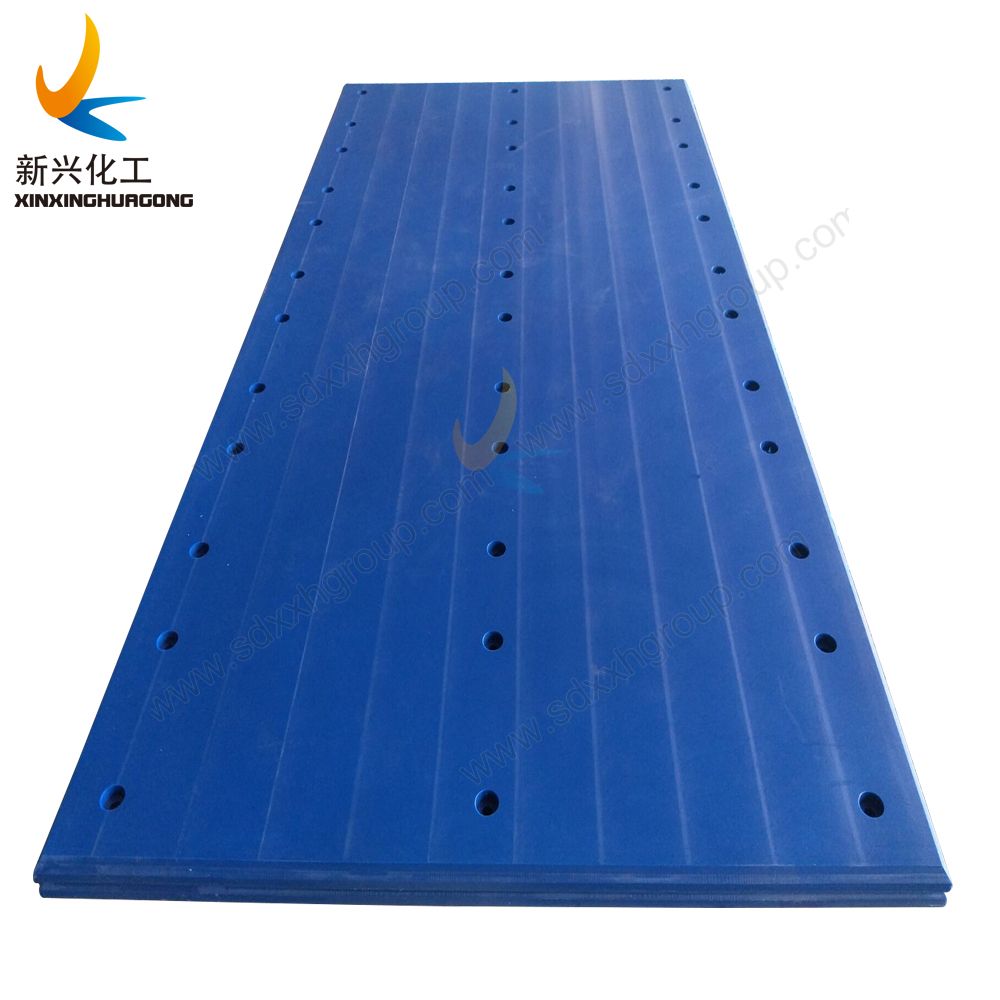

Picture show of UHMWPE sheet/application

abrasion resistant UHMWPE liner for bunker

abrasion resistant UHMWPE liner for bunker

abrasion resistant UHMWPE liner for bunker

abrasion resistant UHMWPE liner for bunker

Abrasion resistant Panel liner Advantages

Extremely high wear resistance:

it is very valuable in engineering application, the ratio of carbon steel, stainless steel, bronze new wear-resisting of even higher.

High shock resistance:

Extremely low coefficient of friction: ultra-high molecular weight polyethylene is very wear-resisting, and low friction coefficient, good self-lubrication, is an ideal bearing bushings, slider, lining material. The use of ultra-high molecular weight polyethylene as friction parts of equipment, besides can improve the wear life, energy saving effect can be received.

Low temperature resistance:

because of ultra-high molecular weight polyethylene is an excellent material toughness, and its low resistance is also very good, in - 269 °C, low temperature, still have certain ductility, and shows no sign of embrittlement.

Technical data of UHMWPE sheet/liners

| PE 1000 Certificate | |||

| Item | Test method | Test result | Unit |

| Molecular weight | ASTM D4020 | 3-4.5 | 1E6 g/mol |

| Density | ISO1183-1 | 0.97 | g/cm3 |

| Yield Strength | ASTM D-638 | 23 | MPa |

| Ultimate Strength | ASTM D-638 | 45 | MPa |

| Breaking Elongation | ISO527 | >250 | % |

| Impact strength | ISO179 | No breaking | Mj/mm2 |

| Abrasion | ISO15527 | 83 | Steel=100 |

| Shore Hardness | ISO 868 | 65 | Shore D |

| Friction Coefficient (Static state) | ASTM D-1894 | 0.11 | Unitless |

| Coefficient of thermal expansion | ASTM D-696 | 0.0002 | 0C |

| Melt point | ASTM D-3417 | 138 | 0C |

Application

UHMWPE liner plate can be applied in bunker, stock bin, funnel, chute and etc. in the following industries: coal, metallurgy, steel, thermal power, cement, coking, glass, separation coal and etc. UHMWPE liner plate can solve the blocking and bonding during production, high-efficiency.

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.