Plastic Machined Parts

Home > Products > By Applicaitons > Plastic Machined Parts > UHMWPE fender panel Polyethene sheetPlastic fenders

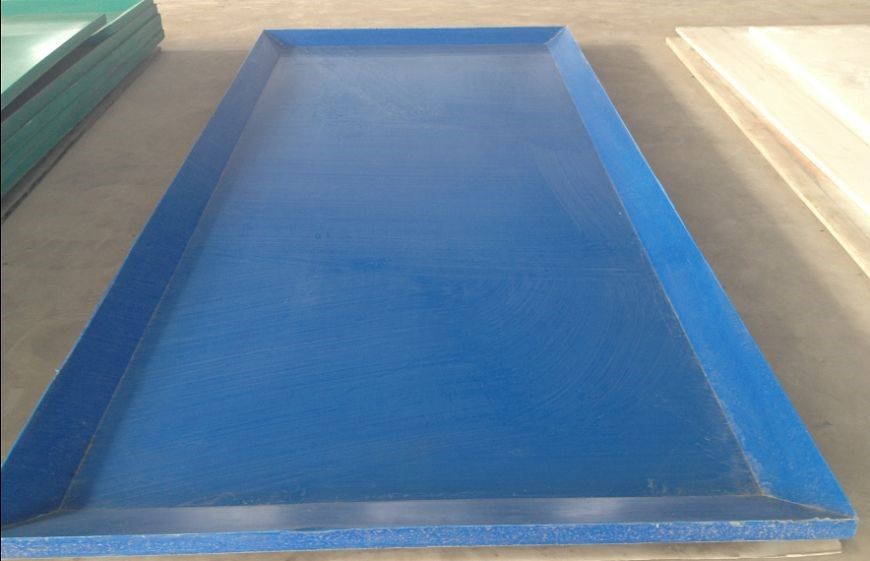

Plastic fender is made of HDPE/UHMWPE, recycled HDPE/UHMWPE. It can be used for the dock guard, pilling, railway sleeper and sea raising enclosure etc for substitution of timber and steel piles. The core attributes of plastic fenders are high strength, erosion-proof, aging proof,long service time and easy for installation etc, now it become applicable in more and more area. Unlike the timber material, plastic fenders is an environmentally friendly material and can be totally recycled at the end of its service life.

Here you can find all kinds of HDPE Sheet you want!

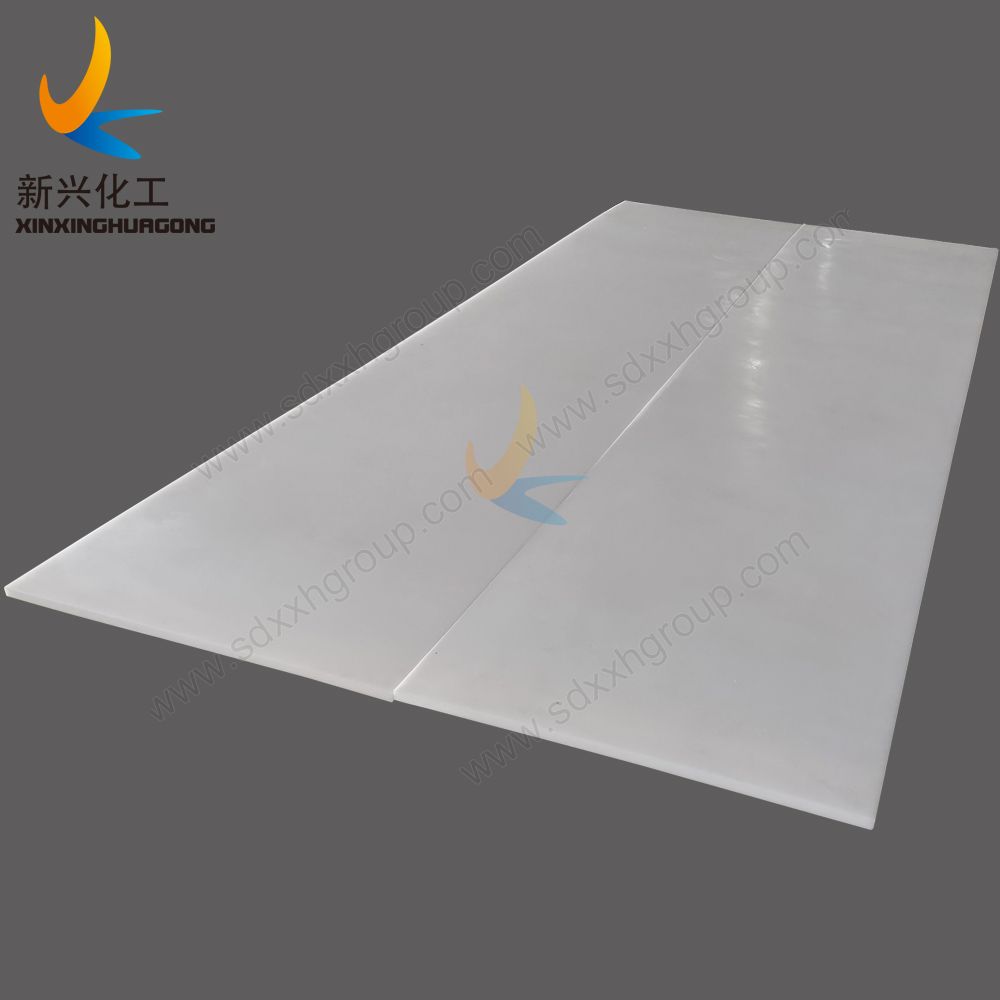

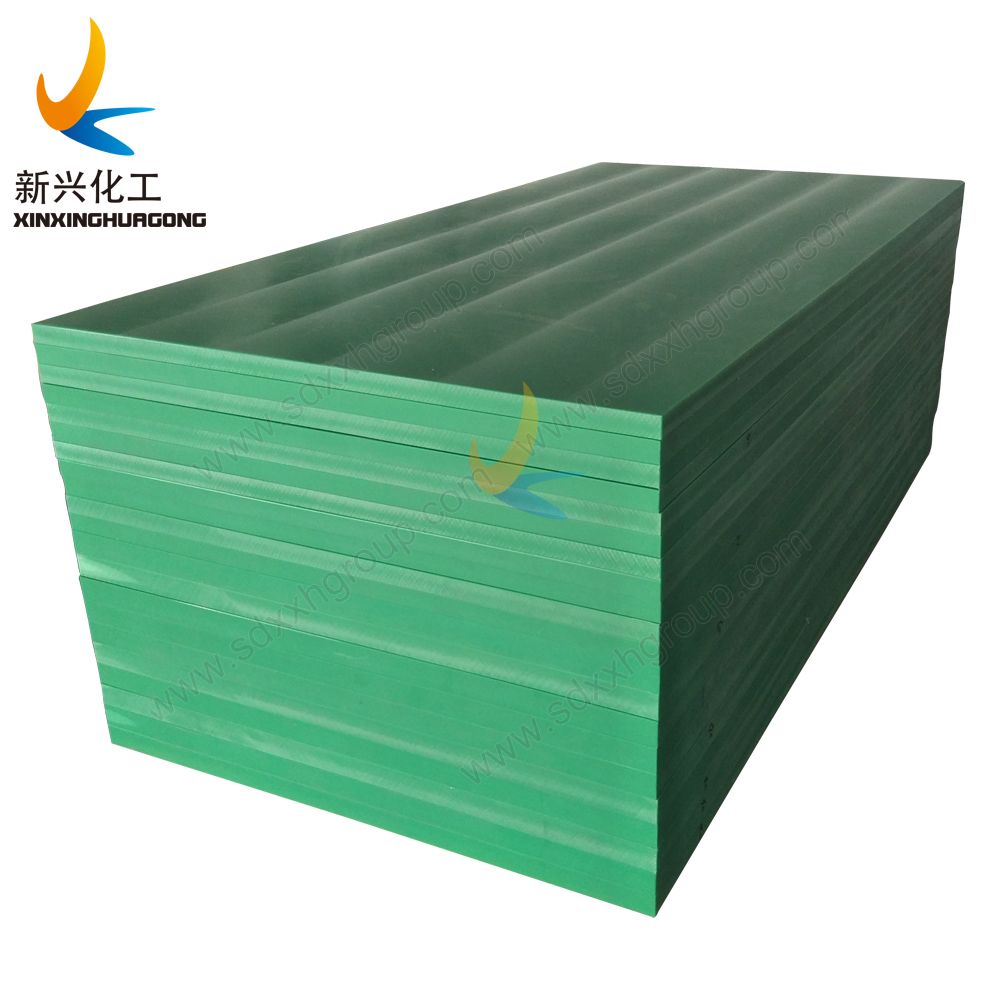

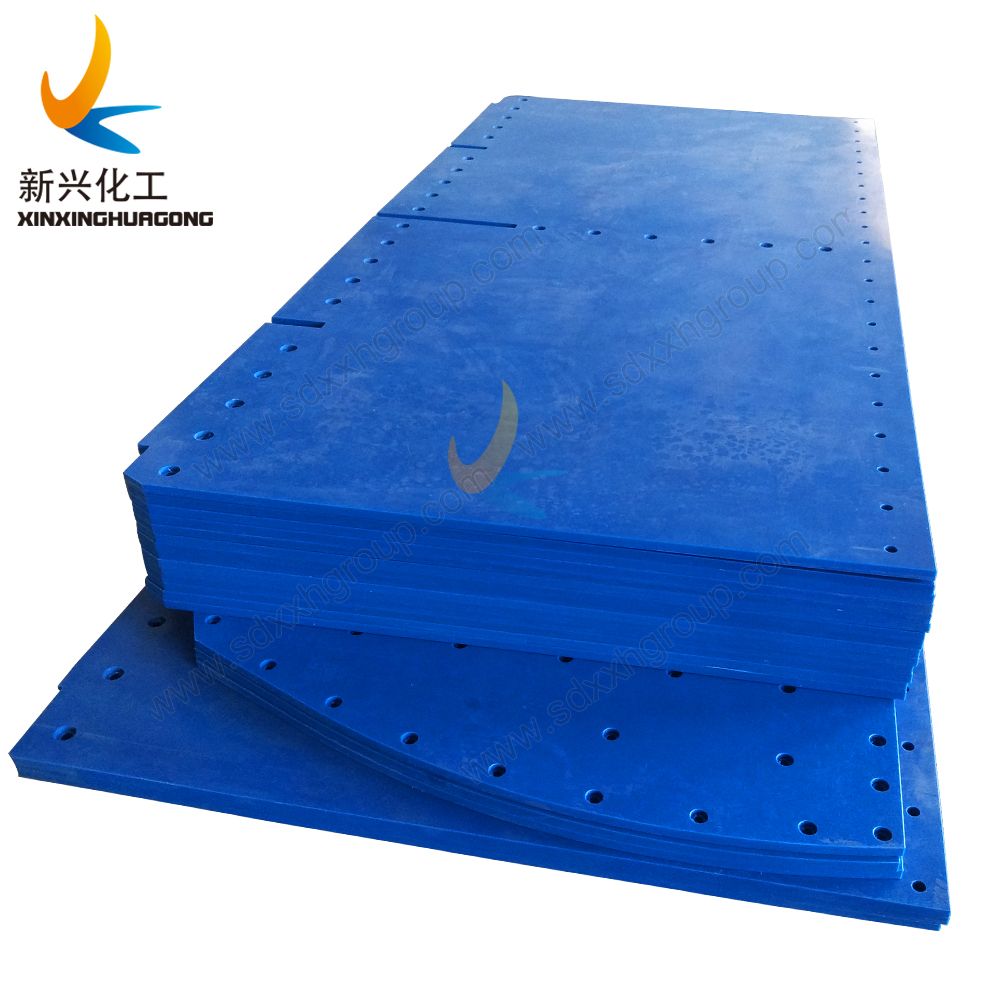

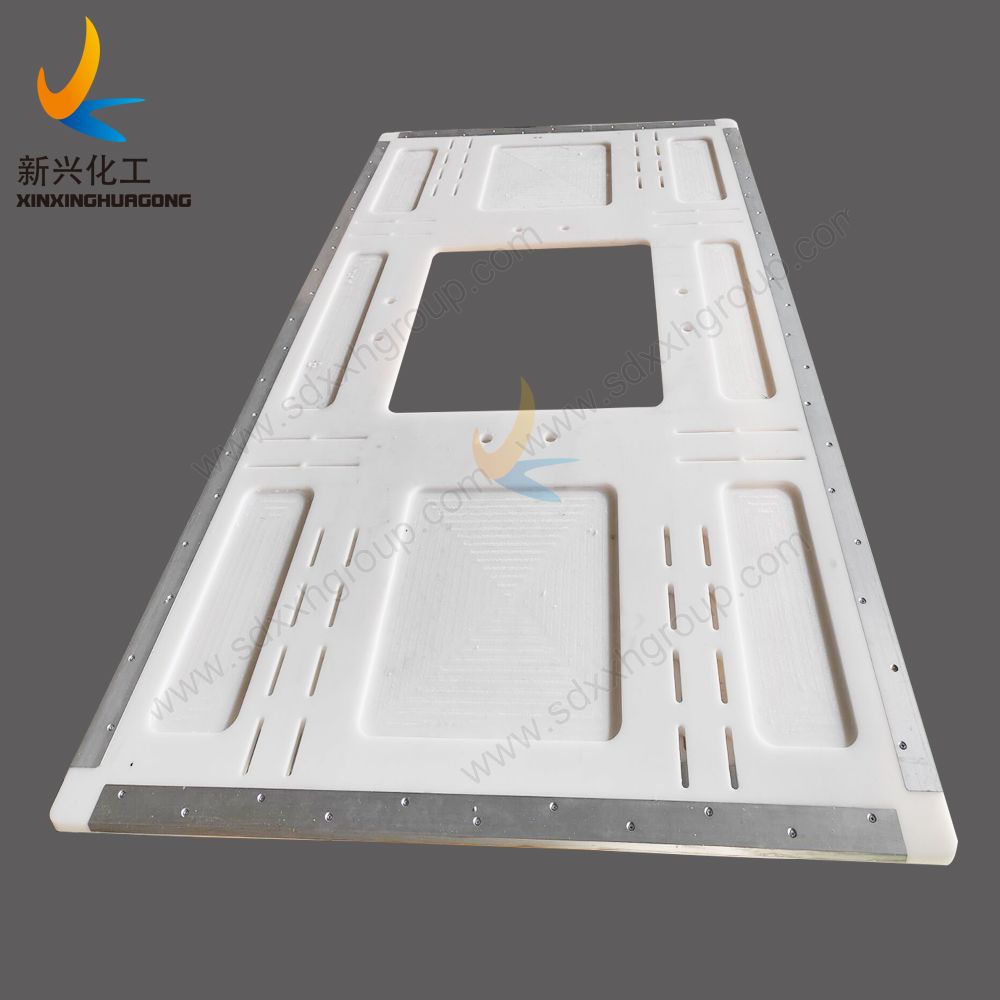

UHMWPE fender panel Polyethene sheet

UHMWPE fender panel Polyethene sheet

UHMWPE fender panel Polyethene sheet

UHMWPE fender panel Polyethene sheet

Advantages of UHMWPE Plastic fender

Features:

Does not decay or rot

Resistant to marine borers, algae and crustaceans

High resistant to UV, Climate extremes, oil spills and pollutants

Easily machined and drilled

Extruded profile with no sharp edges

100% recyclable

![]()

Detail introduction of UHMWPE plastic

UHMW (Polyethylene)

Ultra High Molecular Weight Polyethylene (UHMWPE) has extremely low moisture absorption, a very low coefficient of friction, is self lubricating and is highly resistant to abrasion (10 times more resistant to abrasion than carbon steel). UHMW has the highest impact strength of any thermoplastic presently made and is highly resistant to corrosive chemicals, with an exception of oxidizing acids.

UHMW plastic is known for its durability, machinability, versatility and cost-effectiveness. Virgin UHMW is FDA compliant and is used in applications where high levels of friction are likely to arise including chain channel, wear strips, belt scrapers, guides, and rollers. UHMW can be machined into virtually anything from small bearings to large sprockets and liner systems. Due to an extremely low coefficient of friction, its inherent lubricity minimizes friction resulting in a smooth, noiseless operation.

Outperforming and more cost effective than metal in many applications. UHMW is highly durable and available in a wide variety of formulations and grades.

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.