UHMWPE Fender Pads

Home > Products > By Applicaitons > UHMWPE Fender Pads > UHMWPE marine fender impact resistant facing boardsUltra-high molecular weight polyethylene (UHMWPE) dock fender could avoid the impact damage between ships and dock. Because of the high impact resistance performance, UHMWPE dock fender instead of the traditional steel ones is widely used in ports and docks at home and abroad.

Our UHMW PE-1000 marine fenders are made from virgin uhmwpe material, which is much superior to wood and rubber in building marine constructions or coastal protective structures. UHMW PE-1000 marine fenders allow vessels to glide easily along the surface, protecting hulls and dock structures. Impervious to marine bore worms with minimum cleaning.

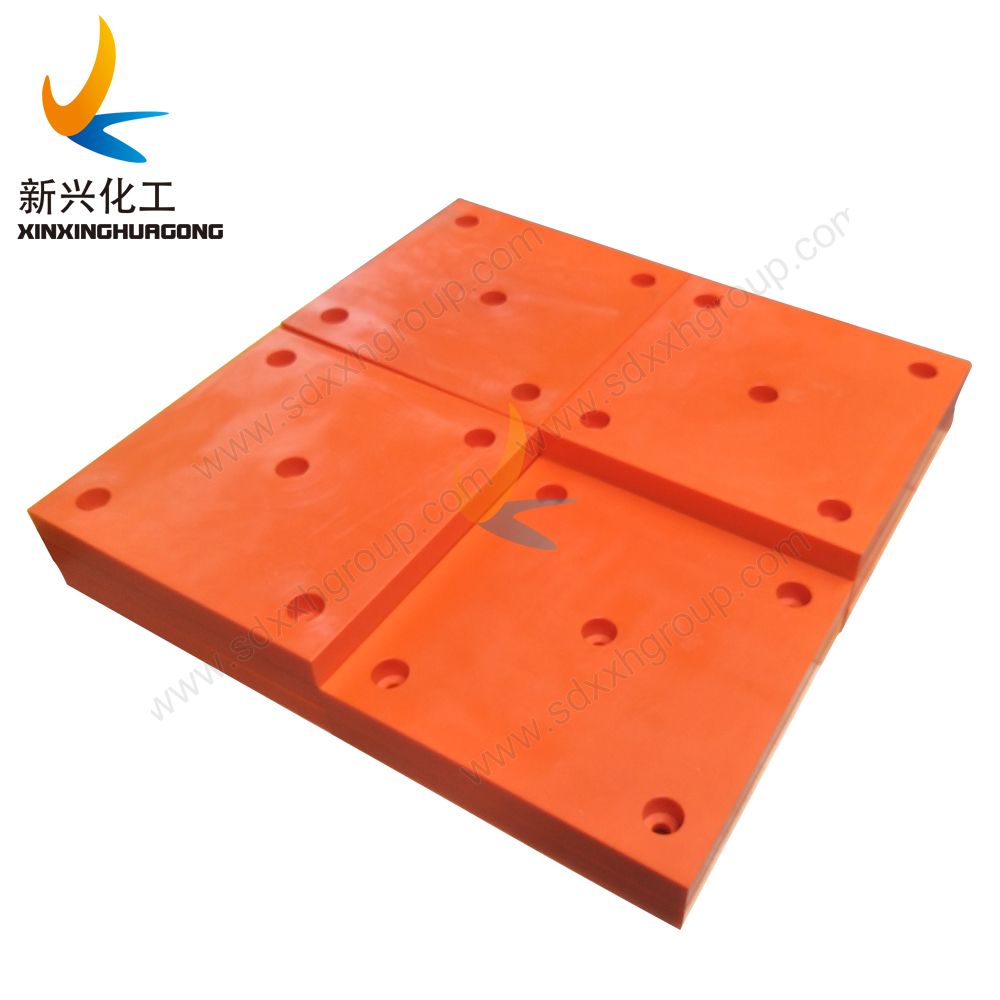

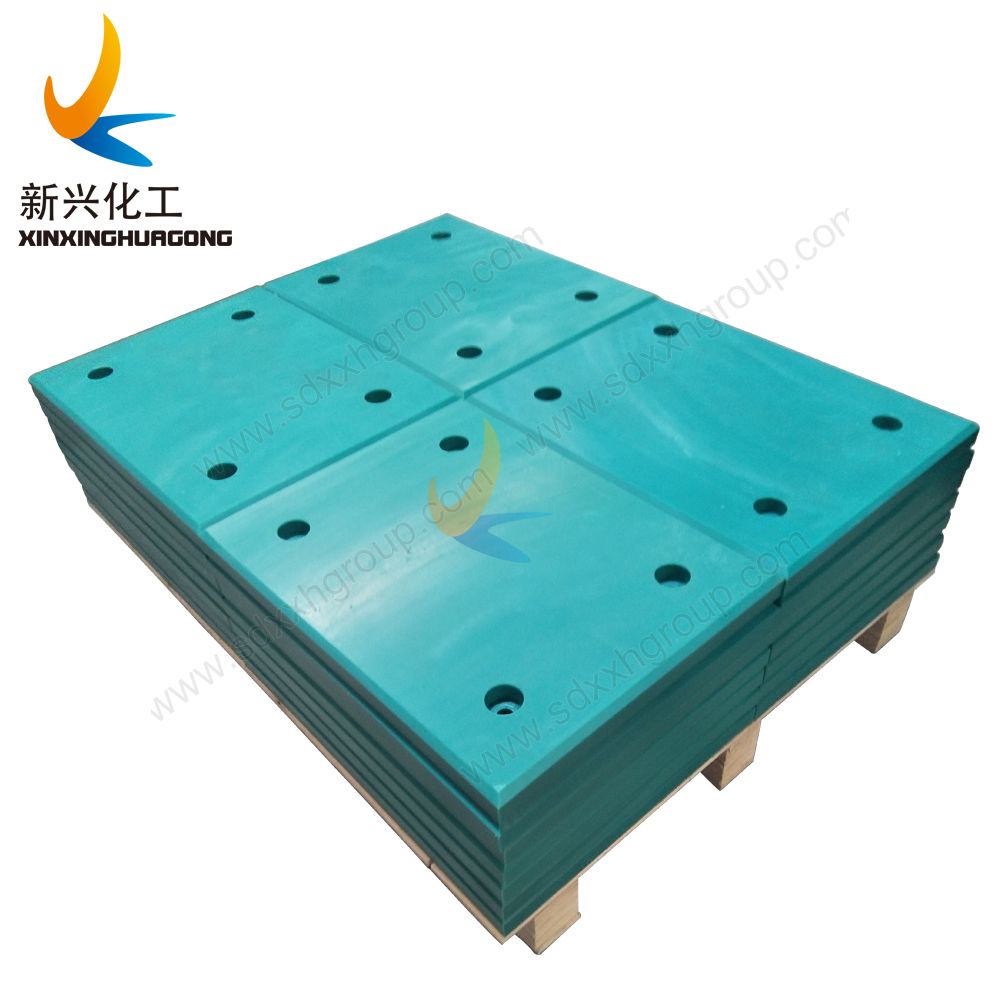

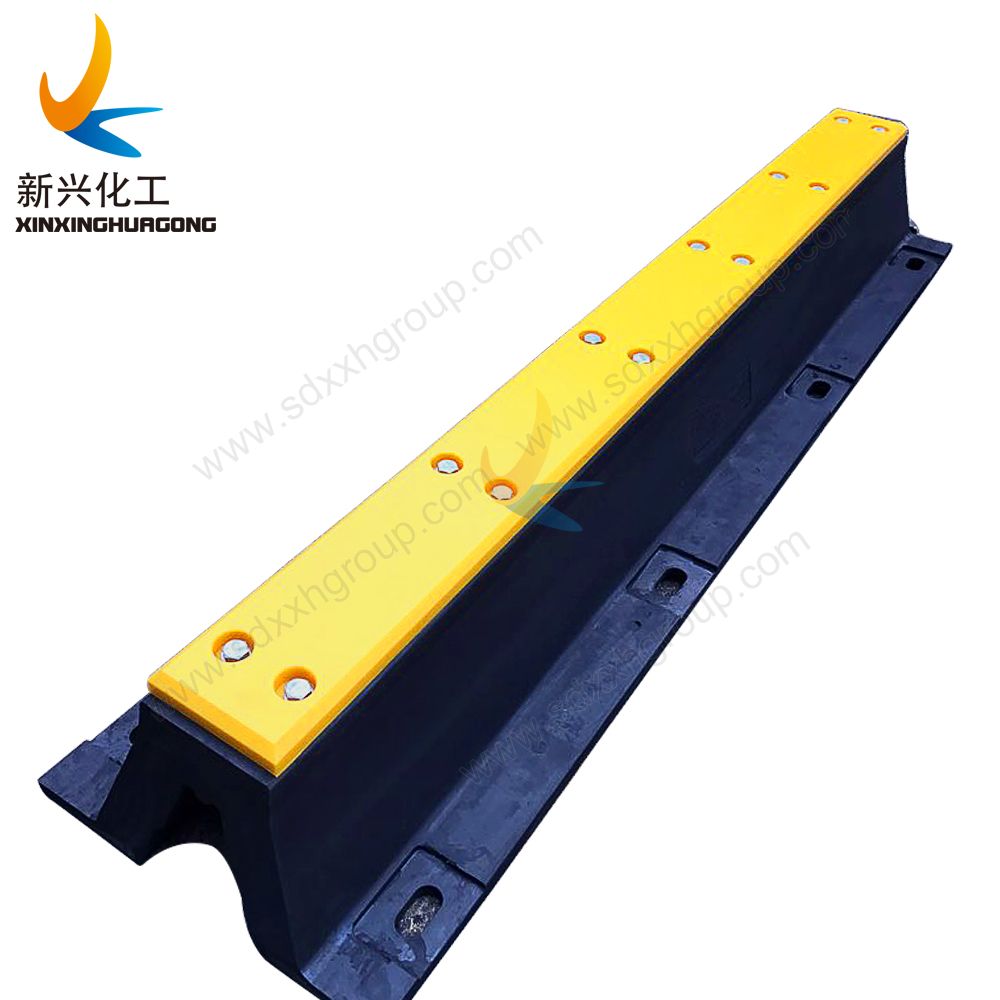

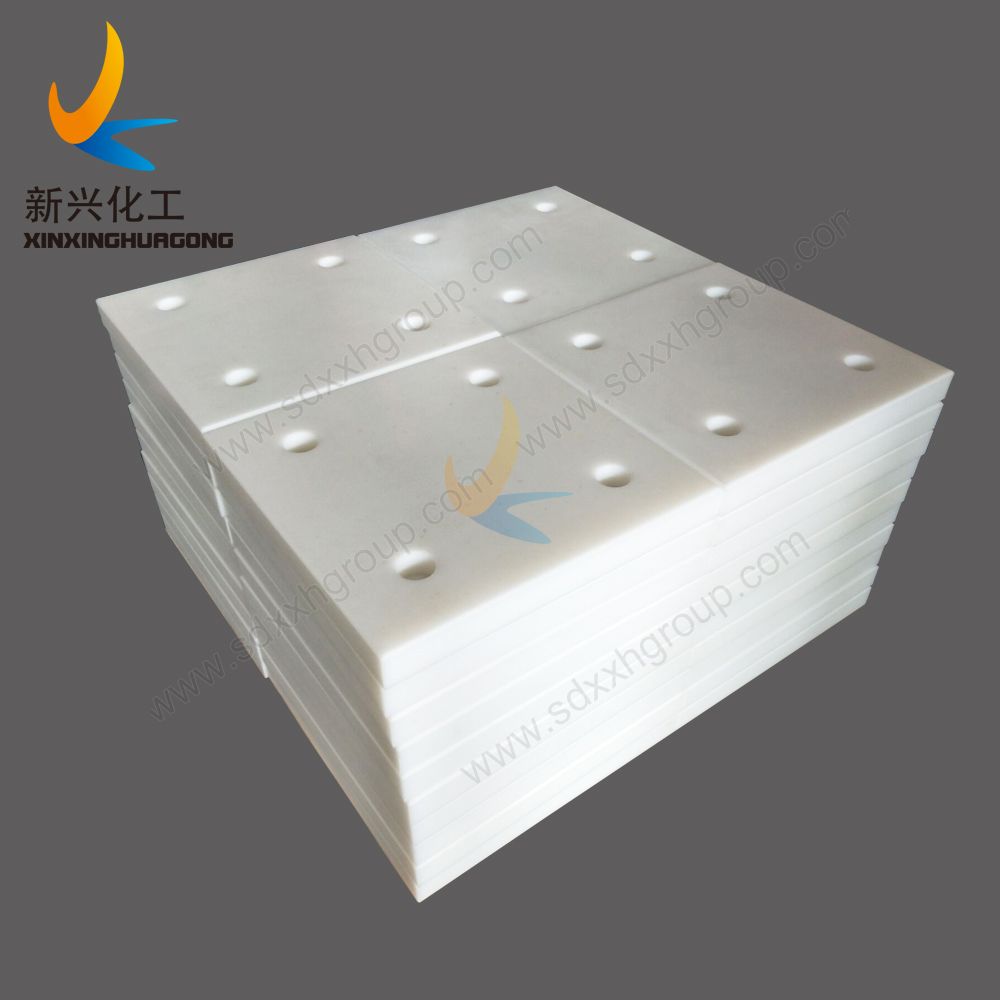

UHMWPE Marine fender facing pads

UHMWPE marine fender impact resistant facing boards

UHMWPE marine fender impact resistant facing boards

UHMWPE marine fender impact resistant facing boards

UHMWPE marine fender impact resistant facing boards

Features of UHMW-PE marine fender pad:

• Extremely high impact strength

• Excellent wear and abrasion resistance

• Optimal sliding properties

• Dimensional stability

• Energy absorption capacity at high loading rates

• Resistance against fatigue

• Water repellent

• Good chemical resistance

• Electrical and dielectric properties

• Physiologically harmless

Technical Parameters of UHMW-PE marine fender panels :

| Property | Unit | Value |

| Density | g/cm3 | 0.93-0.96 |

| Average molecular weight | g/mol | 3million- 10 million |

| Tensile strength (23°C in air) | MPa | 22 |

| Breaking strength | MPa | 42 |

| Tensile strain at break | % | 600 |

| Charpy impact strength (notched) | mJ/mm2 | No break |

| Ball indentation hardness | N/mm2 | 42 |

| Shore hardness | -- | 65-70 |

| Abrasion | % | 70-80, steel = 100 |

| Static Friction Coefficient | -- | ≤0.16 |

| Kinetic Friction Coefficient | -- | ≤0.10 |

| Water Absorption | -- | NIL |

| Elongation at break at 23°C | % | ≥300 |

| Temperature Resistance | °C | -269 to +85 |

| Melt Temperature | °C | 130-140 |

Hdpe Specifications

Application

1.Harbor Construction Boats

2.Individual profiles on quay walls

3.Rubbing Strips

4.Wear Pads to cover wood and rubber

5.Low friction bushings

6.Truck Docks Pilings

7.Fenders for dock plate protection

8.Wear plates and slides

9.Dredges

10.Floating Docks

11.Slide wall fenders to protect

12.Wear plates where dock meets pillage

13.dredge from barges

14.Bushings for pivots

Top

+86 13173332640

Liaohe road, Ningjin county, Dezhou city, 253400, Shandong province, China.